Aquaback’s Distiller Line

Decentralized water treatment systems with various applications

The distiller product strategy focuses on producing two standardized models that are cost-effective and versatile.

Aquaback achieves these solutions through the utilization of mass-produced automated manufacturing techniques, incorporation of readily available off-the-shelf materials and components, and sharing standardized components and subassemblies across different distiller models.

This allows for parallel installation to treat any wastewater volume and offers minimal capacity options.

Products

Small Distillation Recycling Module (SDRM)

Ideal for residential potable water supply, portable potable water supply, and residential advanced septic systems.

Specifications:

Capacity: 20 g/hr (480 g/d) of distillate from 22 g/hr (530 g/d) of influent.

Physical Size: 18 inches in diameter by 40 inches high (5.5 sqft) weighing 80 pounds.

Operating Pressure: 0.8 psi to process most wastewater sources.

Large Distillation Recycling Module (LDRM)

Ideal for wastewater recycling, municipal potable water and green hydrogen solutions.

Specifications:

Capacity: 120 g/h (2880 g/d) of distillate from 132 g/d (3150 g/d) of influent.

Physical size: 38 inches in diameter by 7 ft high (44 sqft) weighing 550 pounds.

Operating Pressure: 0.8 psi to process most wastewater and surface water sources.

The LDRM product will be modified to make a High Pressure Distillation Recycling Module (HPDRM) having a higher powered compressor to produce up to 1.6 psi to distill water having TDS of greater than approximately 10,000 ppm. Other design features will be substantially the same.

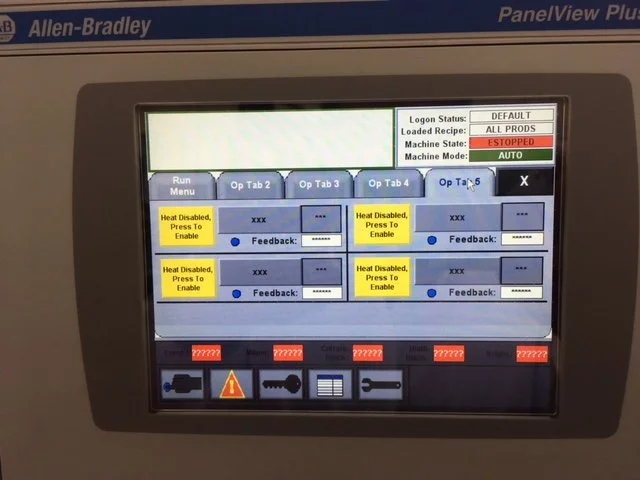

Behind the Scenes: Construction of Aquaback's Distiller

Aquaback is in the process of final design for manufacture to produce distillers to be the central purification device for all application solutions. We have produced many prototypes to refine its design and demonstrate performance. The following pictures show the most recent design which will be produced using modified manufacturing to reduce cost.

Product Stage

We have achieved a technology readiness level of 7, demonstrating operational viability in real-world environments to produce potable water from sewage and other waste waters provided by potential customers.

We are currently accepting non-binding orders for distiller products for various solutions.

We are eager to engage in discussions to explore how our technology can effectively address your unique water challenges, whether through one of our existing solutions or a customized approach tailored to your specific needs.